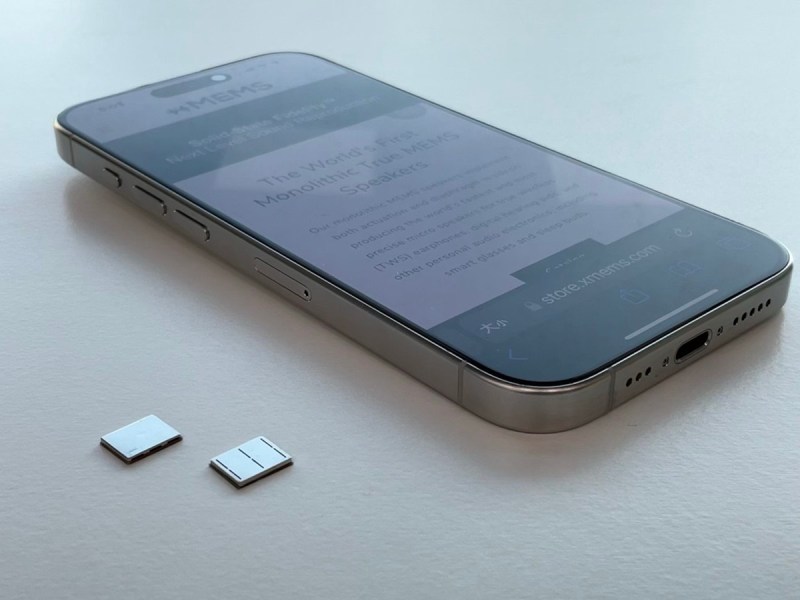

Xmems Labs unveiled its “fan on a chip” micro-cooling components for actively cooling smartphones, tablets and other mobile devices.

These are all-silicon devices — just a millimeter thick — much like the all-silicon micro speakers that the company makes using Micro Electromechanical Systems (MEMS) technology, where the tiny mechanical structures are crafted out of silicon on semiconductor chips, said Joseph Jiang, Xmems CEO, in an interview with VentureBeat. I last spoke with him in July 2020 when the company was introducing its speaker chips, which have now starting to ship in the marketplace.

The company’s tech was previously used for micro-sound solutions. Dubbed piezoMEMS, the tech has now been adapted for use in the company’s Xmems XMC-2400 µCooling chip, the first-ever all-silicon,

active micro-cooling fan for ultramobile devices and next-generation artificial intelligence (AI) solutions.

For the first time, with active, fan-based micro-cooling (µCooling) at the chip level, manufacturers can

integrate active cooling into smartphones, tablets, and other advanced mobile devices with the silent, vibration-free, solid-state Xmems XMC-2400 µCooling chip, which measures just one-millimeter thin.

Join us for GamesBeat Next!

GamesBeat Next is connecting the next generation of video game leaders. And you can join us, coming up October 28th and 29th in San Francisco! Take advantage of our buy one, get one free pass offer. Sale ends this Friday, August 16th. Join us by registering here.

“Our revolutionary µCooling ‘fan-on-a-chip’ design comes at a critical time in mobile computing,” said

Jiang. “Thermal management in ultramobile devices, which are

beginning to run even more processor-intensive AI applications, is a massive challenge for manufacturers

and consumers. Until XMC-2400, there’s been no active-cooling solution because the devices are so

small and thin.”

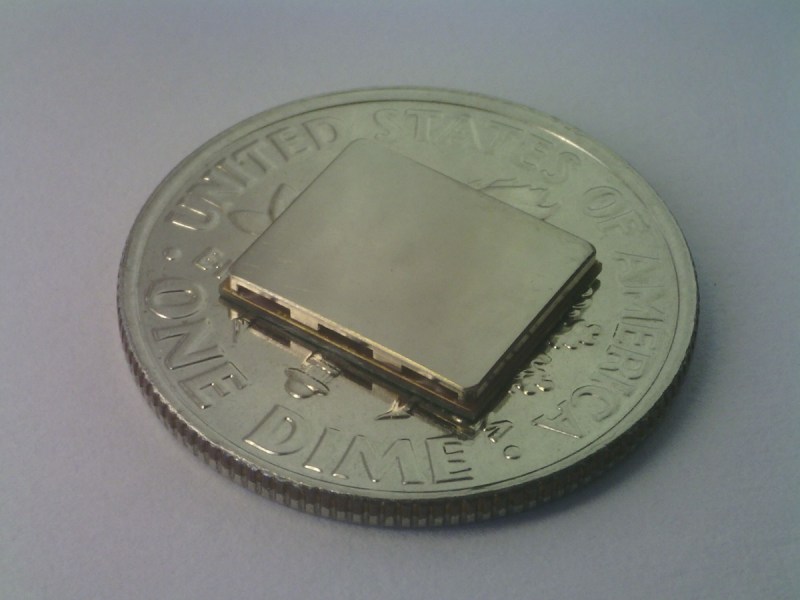

The XMC-2400 measures just 9.26 x 7.6 x 1.08 millimeters and weighs less than 150 milligrams, making

it 96% smaller and lighter than non-silicon-based, active-cooling alternatives. A single XMC-2400 chip can move up to 39 cubic centimeters of air per second with 1,000Pa of back pressure.

The all-silicon solution offers semiconductor reliability, part-to-part uniformity, high robustness, and is IP58 rated. The company will likely get engineering samples back in the first quarter of 2025, and then after that it will hit volume production and eventually ship to customers.

Xmems µCooling is based on the same fabrication process as the award-winning, sound-from-ultrasound, Xmems Cypress full-range micro speaker for ANC in-ear wireless earbuds, which will be in production in Q2, 2025 with several customers already committed to the device. xMEMS plans to sample XMC-2400 to customers in Q1, 2025.

“We brought MEMS micro speakers to the consumer electronics market and have shipped more than half

a million speakers in the first six months of 2024,” Jiang said. “With µCooling, we are changing people’s perception of thermal management. The XMC-2400 is designed to actively cool even the smallest handheld form factors, enabling the thinnest, most high-performance, AI-ready mobile devices. It’s hard to imagine tomorrow’s smartphones and other thin, performance-oriented devices without Xmems µCooling technology.”

Xmems will begin demonstrating XMC-2400 to lead customers and partners in September at its Xmems Live events in Shenzhen and Taipei.

Founded in January 2018, Xmems Labs has been granted more than 150 patents for its platform technologies. The company has 70 employees. It’s a “fabless chip” firm, which means it designs chips that are manufactured by contract chip makers. The company is based in Santa Clara, California, and it has raised about $75 million.

How it works

For the speakers, Xmems created structures like small air pumps in silicon. They’re now in mass production. The underlying technology is piezoMEMS, which uses a thinfilm piezo layer as the screen layer. It moves, or actuates, by applying a voltage to the material.

“By applying voltage, we can make MEMS structures inside of a chip move at different rates of speed. That’s the fundamental IP around what Xmems does with our sound generation products,” Jiang said. “We put them under the brand of micro fidelity. They make fantastic sound. They’re now entering the market.”

The fan gives designers more options by pushing or pulling air or cooling air. The designers can put the chip on a printed circuit board or mount it on a chip. It can be vented on the side or top. And it’s a fraction of the size of other chips in a system. There is also no noise because it operates in the ultrasonic band, inaudible for the human ear. And it does not have to be placed on top of a CPU. In this respect, a system would still use separate heat-spreading devices to get heat away from a chip.

“This is a very tiny device. If we look at the airflow per package volume, we are significantly more efficient,” he said.

Customers will determine just how many fans on how many chips they will use in their final products.

“We’ll be working with our early alpha customers in these markets to determine the right mix,” Jiang said.

In some ways, it will be easier to get the tech into the market the second time around, as it has already been battle tested in one market, Jiang said.

“We have multiple millions of units per month of capacity in place,” Jiang said.

And it has more than one chip manufacturer to make its chips. That makes its supply chain more reliable. If you put your finger near the device, you’ll feel cold air blowing out of it.

As far as timing goes, the company contemplated this product at its inception. But it turned out to be easier to tackle the audio chips first. After that was done, the company took a more serious stab at the micro-cooling chip.

These sound chips go into wireless stereo earbuds, and there is a new generation of speaker chips coming dubbed Cypress, which is in the ultrasonic space.

The fan uses similar technology.

“This is essentially a voltage-controlled airflow transducer, and we took a look at using it for cooling instead of sound generation,” Jiang said. “We can move these MEMS structures fast enough now to generate a substantial amount of airflow. That’s the starting point for our micro-cooling technology.”

I asked why it took so long to get the speaker chips in the market.

“Anytime you have a new way of doing things, [it takes time]. The coil and magnet speaker have been around for a century. Getting it to market is another ordeal less to do with with us our technology, which matured quite quickly,” he said. “It’s about getting the consumer electronics manufacturers to adopt and change their ways.”

As we shift from mechanical to silicon devices, the tech is more reliable. The solid state drive finally caught up with hard disks and have pretty much outstripped hard drives on speed and storage capacity in may applications. Hard drives still have a cost advantage, but have moved into different applications.

“We’re in the process of moving the speaker from a multistage mechanical, century-old coil magnet technology into silicon,” Jiang said. “And now this spinning fan, which is they just can’t shrink enough to get into small thin form factor electronics, is next. We’re again using silicon innovation to shrink the size, improve the performance and get active cooling into modern electronics.”

The company notes that consumer electronics companies are still touting thinness as a major feature of their devices in their marketing. Thermal management is still a big problem in smartphones. I played Call of Duty: Warzone on my iPhone 15, and it made the phone run hot very quickly.

The phones now have 5G, multiple radios, and increasingly powerful CPUs and GPUs thanks to AI. The increasing computational requirements come from things like manipulating photos and videos using AI. These devices are passively cooled now using heat spreaders or vapor chambers because they can’t fit traditional fans, which are typically three millimeters or more in thickness, or three times the size of the micro-cooling solution. That means the solution can only take heat source and spread it throughout the device, rather than cool it using air flow. As a result, they have to throttle a processor to stop the heat.

“Taking AI to the edge is just going to bring even more challenges to thermal management of these mobile devices,” said Jiang. “There really is no fan that can fit inside of a mobile phone today, it’s just too thick.”

Source link